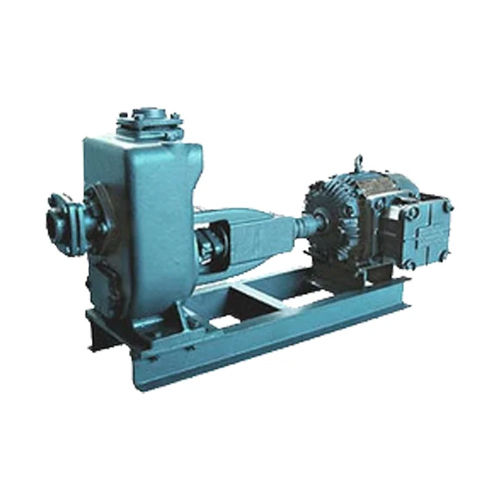

Self Priming Dewatering Coupled Pump

Self Priming Dewatering Coupled Pump Specification

- Voltage

- 220-240V

- Inlet/Outlet

- 3 inch x 3 inch

- Head Size

- Up to 28 meters

- Caliber

- 75 mm

- Working Temperature

- Up to 80C

- Control System

- Manual/Automatic Control Panel

- Theory

- Centrifugal Pump

- Mounting Type

- Base Mounted

- Flow Rate

- Up to 800 LPM

- Frequency

- 50 Hz

- Max Suction

- 8 meters

- Discharge Pressure

- Max 4 bar

- Noise Level

- <85 dB

- Speed

- 2900 rpm

- Usage

- Industrial

- Material

- Stainless steel

- Structure

- Horizontal

- Power

- 2.2 kW

- Product Type

- Self Priming Dewatering Coupled Pump

- Standard

- High

- Fuel Type

- Electric

- Color

- Green

- Pressure

- Up to 4 bar

- Application

- Dewatering, Sludge Handling, Liquid Transfer

- Suction Type

- Single suction

- Seals Type

- Mechanical Seal

- Priming

- Self priming

- Pump Type

- Coupled Pump

- Capacity

- 0.8 m/min

- Service

- On-site support available

- Suitable Liquid

- Water, Slurry, Sludge

- Motor Protection

- IP55

- Weight

- Approx. 60 kg

- Cooling Method

- Air Cooled

- Packaging

- Standard Export Packing

- Additional Product Specifications

- Install Type

- Surface installation

- Automation Grade

- Semi-automatic

- Impeller Type

- Non-clog, Cast Iron

Self Priming Dewatering Coupled Pump Trade Information

- Minimum Order Quantity

- 10 Units

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 100 Units Per Week

- Delivery Time

- 7 Days

- Main Domestic Market

- All India

About Self Priming Dewatering Coupled Pump

| Power | 1-25 HP |

| Motor Horsepower | 2 - 5 HP |

| Power Source | Electric |

| Engine Type | Motor driven |

| Engine Horsepower | 1-25 HP |

| Product Type | Dewatering pump |

| Brand | Kirloskar / IMA |

| Head | Upto 30 meter |

| Max Flow Rate | 5000 LPM |

| Model | SP type from 1 inch to 6 inches |

Engineered for Industrial Dewatering Needs

Designed for demanding industrial applications, the Self Priming Dewatering Coupled Pump efficiently manages water, slurry, and sludge. Its powerful 2.2 kW motor, robust build, and high flow capacity make it a reliable solution for factories, construction sites, and wastewater plants. The pumps surface installation and base-mounted configuration ensure ease of set-up and stability during operation.

Durable and Easy to Maintain

Constructed from high-quality cast iron and stainless steel, the pump resists wear from abrasive materials. The non-clog impeller and mechanical seal system help prevent blockages and reduce maintenance demands, while on-site support is available for quick troubleshooting. Standard export packaging guarantees safe transport to sites across India.

Flexible Installation and Operation

Suited for horizontal mounting and single suction, the pump comes with manual or automatic control panel options for operational flexibility. The air-cooled system and IP55 motor protection ensure safety and long lifespan, even in high-temperature environments up to 80C. Designed with industrial users in mind, it is adaptable to various control systems and capacity needs.

FAQs of Self Priming Dewatering Coupled Pump:

Q: How does the self priming feature benefit dewatering operations?

A: The self priming capability allows the pump to automatically evacuate air from the system, enabling rapid start-up and continuous operation without manual priming. This reduces downtime and increases efficiency when transferring water, slurry, or sludge in demanding industrial environments.Q: What types of liquids can this pump handle effectively?

A: This pump is engineered to efficiently handle water, slurry, and sludge, making it suitable for a range of industrial applications such as construction site dewatering, wastewater management, and general liquid transfer tasks.Q: When should I consider using a non-clog impeller pump?

A: A non-clog impeller pump is ideal when dealing with liquids that may contain solids, fibrous materials, or sedimentsas often found in sludge or slurry. It minimizes blockages, ensuring steady operation and reducing maintenance intervals.Q: Where can the Self Priming Dewatering Coupled Pump be installed?

A: This model is designed for surface installation and is best suited for industrial locations like construction sites, factories, wastewater facilities, or any site requiring robust dewatering and liquid transfer capabilities.Q: What process does the pump use for cooling and motor protection?

A: The pump uses an air-cooled system to maintain motor temperature, coupled with IP55-rated protection to safeguard against dust and water ingress, enhancing the units lifespan and reliability during extended operations.Q: How does the semi-automatic control system enhance usage?

A: The semi-automatic control allows operators to switch between manual and automatic modes, promoting operational flexibility. This is particularly valuable in variable work environments, giving users precise control over pump starting, stopping, and monitoring parameters.Q: What are the main benefits of selecting this pump for industrial applications?

A: Key advantages include high flow rates up to 800 LPM, the ability to handle challenging fluids, low maintenance due to robust construction, easy surface installation, and reliable onsite support. Its durability and efficient operation make it an asset for any industrial dewatering project.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Monoblock Pump Category

Self Priming Monoblock Mud Pump

Minimum Order Quantity : 1 Unit

Material : Stainless steel

Color : Blue

Usage : Industrial

Application : Submersible

Power : Other, 1.5 HP

High Speed Monoblock Pump

Minimum Order Quantity : 1 Unit

Material : Metal

Color : Blue Paint Coated

Usage : Water

Power : Electric

Single Phase Monoblock Pump

Minimum Order Quantity : 1 Unit

Material : Stainless steel, Cast Iron

Color : Green

Usage : Cryogenic, Fire, Maritime, Metering, Sewage, Submersible

Application : Submersible, Cryogenic, Maritime, Metering, Sewage